92% Alumina Ceramic Ball High Alumina Inert Ceramic ball

| Product | Inert Ceramic ball |

| Type | Ceramic Ball |

| Material | High Density High Hardness 92% Alumina material |

| Shape | Sphere |

| Application | Catalyst Bed Support, Water Treamtnet |

| Density | 3.2g/m3 |

| Quality | Superior |

| Delivery | Fastly |

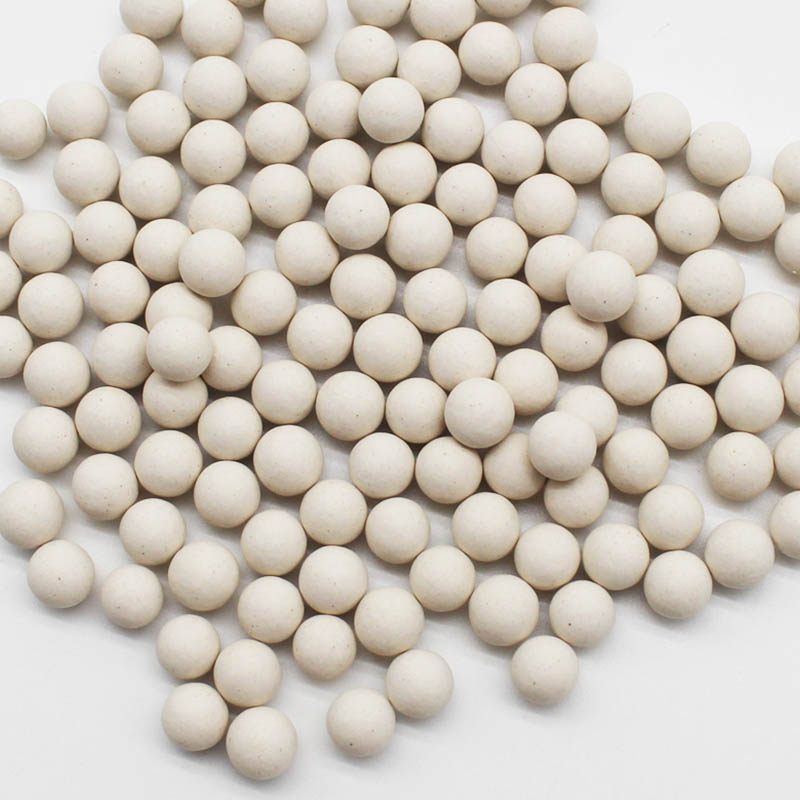

2.The Picture of Product

Our One of production angle.

Ceramic Inert balls

1. can be as a water treatment filter

2. as a catalyst carrier

3.Towerr packing

Ceramic Ball ,Catalyst Carrier for Packing Level

High Strenght

Chemical composition of Ceramic Inert Balls

| Typical Technical Composition | Min. % | Max. % | Usual % |

SiO2 | 64.00 | 75.00 | 68.40 |

Al2O3 | 19.00 | 26.00 | 24.50 |

Fe2O3 | ****** | 1.60 | 0.94 |

TiO2 | ****** | 1.40 | 0.96 |

CaO | ****** | 0.65 | 0.42 |

MgO | ****** | 0.60 | 0.38 |

Na2O | ****** | 2.00 | 1.12 |

K2O | ****** | 3.50 | 3.28 |

Al2O3 + SiO2 | 90.00 | 96.00 | 92.90 |

Physical properties of Ceramic Inert balls

Index | Value | Value |

Leachable Iron | ≤ 0.1% | ****** |

Apparent Porosity by Weight, dia. ≥ 10mm | ≤ 0.4% | ****** |

Apparent Porosity by Weight, dia. = 6mm | ≤ 1.0% | ****** |

Apparent Porosity by Weight, dia. = 3mm | ≤ 3.0% | ****** |

Moh's Hardness Scale | >6.5 | ****** |

Water Absorption | <1.0wt.% | ****** |

Acid Resistance | >99.8% | ****** |

Thermal Conductivity | 0.9-1.0 w/m 2 .k | ****** |

Thermal Expansion @ 500 | 0.20% | ****** |

Specific Heat | 628-837 j/kgq | ****** |

Thermal Shock Stability, 500 then water cooling | 10 times | ****** |

Max. Operating Temperature | 1050 | 1922 |

Specific Density | 2,300 kg /m 3 | 144 lb /ft 3 |

Bulk Density (Packing Density) | 1,350 g /cm 3 | 84 lb /ft 3 |

Crush Strength of Ceramic balls

Size / | Crush Strength | |||

Nominal Size | (lbs) | (kg) | (N/pc) | |

mm | Inch | min. | min. | min. |

3 | 1/8 | 50 | 23 | 225 |

6 | 1/4 | 123 | 56 | 550 |

10 | 3/8 | 202 | 92 | 902 |

13 | 1/2 | 385 | 175 | 1716 |

16 | 5/8 | 520 | 236 | 2315 |

19 | 3/4 | 978 | 444 | 4355 |

25 | 1 | 1428 | 648 | 6355 |

38 | 1-1/2 | 2020 | 916 | 8983 |

50 | 2 | 2987 | 1355 | 13288 |

| Company Show |

1. About us

Pingxiang Zhongying Packing Co., Ltd., which is located in Pingxiang City, Jiangxi Province, the hometown of ceramics, is a manufacturer of petrochemical and environmental protection packing and catalyst, such as molecular sieves, activated aluminum, inert alumina ceramic ball, ceramic packing, plastic packing, metallic packing, honeycomb ceramics, catalyst bed support media, activated carbon, petrochemical additives, ceramic filter, water treatment filter etc.

Our factory is situated in Xiangdong Industrial Park in Pingxiang City,and it covers an area of 70000 square meters, with a construction area of 30000 square meters and fixed assets worth RMB17.5 million.For better development and international standards, our company has passed ISO9001-2000 quality system certification. Our product has been widely used in petroleum, chemical industry, metallurgy, electric power, environmental, pharmaceutical, aerospace, aviation and other industries. Our product sells well at home and abroad.

2. Why Choose us

1) Complete production line, quick delivery

2) Advanced equipments, good quality

3) Professional skills, all-related services

Factory Tour

Production Process

3. Certifications

4. Our Markets

| Main Markets | 20.00% North America |

| 20.00% South America | |

| 15.00% Eastern Europe | |

| 10.00% Southeast Asia | |

| 10.00% Africa | |

| 5.00% Oceania | |

| 5.00% Northern Europe | |

| 5.00% Southern Europe | |

| Total Annual Sales Volume | US$2.5 Million - US$5 Million |

| Export Percentage | 51% - 60% |

5. General Question

1.a. Are you Trading Company or Factory:

b. We have more than 20 experience year production in this line .

2.a. What's your production ability for one month?

b. We can product 1000 metric ton for one month .

3.a. What's your MOQ?

b. 1 metric ton is available .

4.a. What's your shipping port?

b. Shenzhen,Shanghai and any port in China

5.a. What's your Payment Terms?

b.L/C,D/A,D/P,T/T,Western Union

6. Contact

Try order is acceptable. Sample is available.

Welcome to inquire, we will feedback within 24 hours.

Inert ceramic ball are used as catalyst, absorbent, desiccant and drying agent in petroleum, chemical, fertilizer, natural gas and environmental protection industries. As a catalyst reactor coverage tower packing materials and support, the major role is to increase distribution of gas or liquid, support and protect the intensity of low strength activity catalyst.

Derechos de autor © Jiangxi Xintao Technology Co., Ltd. | Reservados todos los derechos

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist