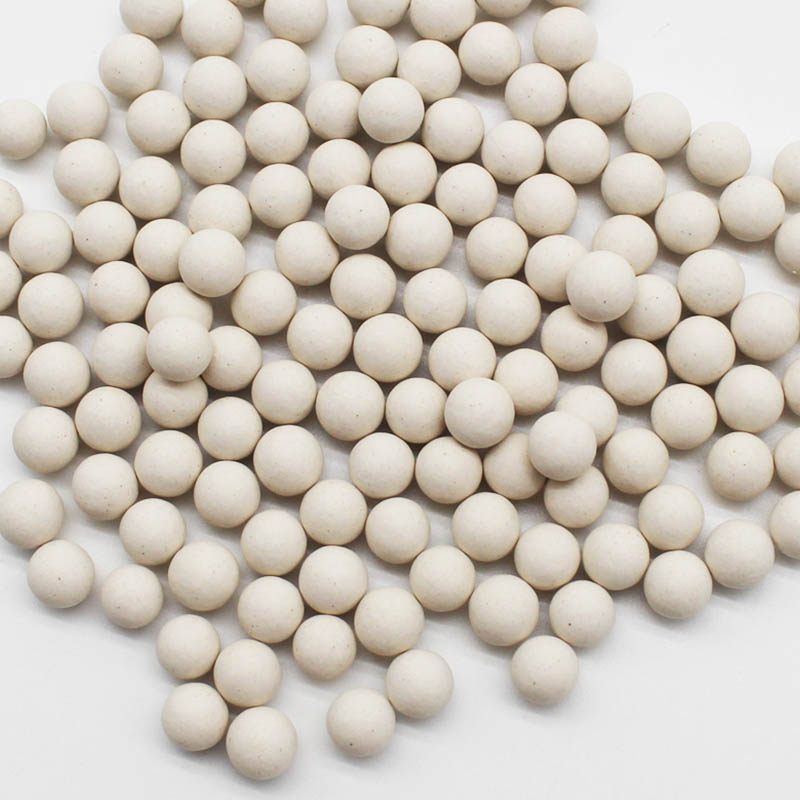

Support media catalyst carrier Inert Ceramic Ball

HS:6909110000

Characteristics:

Inert Ceramic Ball has stable chemical features and a low rate of water absorption, resistant to high temperature and high pressure. It is also resistant to the corrosion of acid, alkali and some other organic solvents. They can stand the rapid changes in temperature during the manufacturing process.

Inert Alumina Ceramic Ball is widely used in petrochemical industry, chemical industry, fertilizer industry, natural gas industry and environment protection, etc. Which function mainly as the covering and supporting materials for catalyst in reactors and packing for towers. Its principal role is to accelerate the distribution of gas or liquid, and support or protect the active catalyst, which has the relevantly lower mechanical strength.

Technical Specifications:

| Specification | Common Ceramic Ball | Inert Ceramic Ball | Medium Alumina Ball | High Alumina Ball | 99% Alumina Ball |

| Al2O3 + SiO2 (%) | >93 | >92 | >93 | >94 | >99 |

| Al2O3 (%) | 17-23 | 23-30 | 47-56 | 90-93 | 99 |

| Fe2O3 (%) | <1 | <1 | <1 | <1 | <1 |

| CaO (%) | <0.5 | <1.5 | <2 | <4 | 0.2 |

| MgO (%) | <0.5 | <2.5 | <0.5 | <0.5 | 0.1 |

| K2O + Na2O (%) | <4 | <4 | <3.5 | <4 | >0.5 |

| TiO2 | <0.5 | <0.1 | <0.1 | 0.5 | |

| Leachable Iron (%) | <0.1 | <0.001 | <0.001 | ||

| Water Absorption (%) | <0.5 | <0.2 | <2 | <3 | 2.0-6.0 |

| Bulk Density (g/cm3) | 1.35-1.40 | 1.35-1.40 | 1.35-1.45 | 1.8-2.0 | 1.8-2.0 |

| Operation Temp. max. | >1100 | >1100 | 1480 | 1760 | |

| Mohs Hardness (scale) | >6.5 | >7 | >7 | >7 | >7.5 |

| Crush Strength | KN/particle | ||||

| 1/4 inch (6mm) | >0.5 | >0.54 | >0.56 | >0.44 | >1 |

| 1/2 inch (13mm) | >1.5 | >1.67 | >1.56 | >1.99 | >3 |

| 3/4 inch (19mm) | >4.15 | >4.21 | >2.89 | >3.21 | >5 |

| 1 inch (25mm) | >6.07 | >6.22 | >4.89 | >5.33 | >8 |

| 1-1/2 inch (38mm) | >8.52 | >8.92 | >5.33 | >5.28 | >8 |

| 2 inch (50mm) | >9.7 | >9.8 | >6.22 | >8 | >15 |

Packing:

1,25Kg/Bag,1.25Mt per fumigated-free pallet

2,Steel drum

3,Jumbo bag,1Mt/Bag

Application:

It is used as the covering, packing and supporting materials of the catalyst in reactors and columns in varied areas.it broadly utilized in petroleum, chemical industry, chemical fertilizer, natural gas, and environmental protection fields,etc.

Why choose Sinoshine?

1.Can I get free samples?

Yes, we can offer free samples within 1.0kg base on freight collected.

2.What's your payment terms?

30% deposit in advance,70% balance to be paid against the B/L copy.

3.What's your delivery time?

Production time: 15-25 days after deposit payment received.

4.Are you manufacturer or trading company?

We are manufacturer and exporting company, the factory is located Zibo, Shandong Province, China.Welcome to visit our company in any time.

5. Why choose Sinoshine?

Professional sales and technology team provide service.

Professional producing process and strict QC team

Reasonable price

Shipment on time

We are experienced in industrial ceramic. We already export to America,Chile,Ecuador,Korea,Iran,Australia,Malaysia,Indonesia and so on.

Maybe you interested related products:

Derechos de autor © Jiangxi Xintao Technology Co., Ltd. | Reservados todos los derechos

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist